Welding equipment

SL4-FF EVO Wood

The world's first and only 4-head CNC welding machine that completely eliminates the welding bead from the corner and allows profiles to be welded with a joint that simulates the assembly angle of a wooden window frame on one side.

The machine, which is unique in its kind, performs both seamless welds with a conventional 45 ° angle and "Wood appearance" closures, in which one side is welded 45 ° and the other side 90 °, while maintaining uniform quality and excellent aesthetics.

The machine, which is unique in its kind, performs both seamless welds with a conventional 45 ° angle and "Wood appearance" closures, in which one side is welded 45 ° and the other side 90 °, while maintaining uniform quality and excellent aesthetics.

SL5-TFF

A very high precision system, more than a welding machine, the SLFF-5TV is a real manufacturing center, a complete machine that allows the simultaneous welding of the 2 outer corners of the switchboard, within which I have 1, 2 or 3 trenches.

This is a 5 Heads line specifically for those markets that require luminaire crossmembers to weld in “V” mode: the corners of the profile are welded 90 ° while, thanks to the 3 modern central heads, the crossmembers are connected by Notch Transom welding.

This is a 5 Heads line specifically for those markets that require luminaire crossmembers to weld in “V” mode: the corners of the profile are welded 90 ° while, thanks to the 3 modern central heads, the crossmembers are connected by Notch Transom welding.

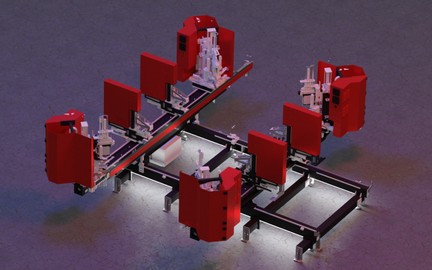

SL8-TFF EVO

The world’s first and only 8 CNC-head welding machine that completely eliminates the welding edge from the corner, allowing you to obtain PVC windows with consistent quality and excellent aesthetics.

The natural development of the 4-head SL4-FF Evo thanks to the 4 extra heads allows you to easily weld the 4 corners of the Pvc frame with 2 crosses (front welding), without cleaning (patented seamless welding) or retouching.

The natural development of the 4-head SL4-FF Evo thanks to the 4 extra heads allows you to easily weld the 4 corners of the Pvc frame with 2 crosses (front welding), without cleaning (patented seamless welding) or retouching.

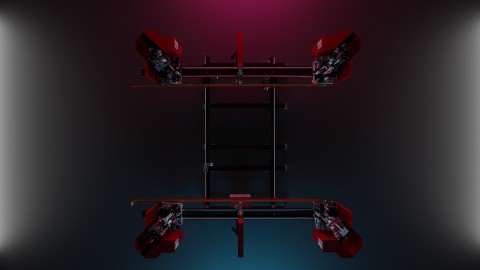

SL6-TFF EVO

The world's first and only 6 CNC-head welding machine that completely eliminates the welding edge from the corner, allowing you to obtain PVC windows with consistent quality and excellent aesthetics.

The natural development of the 4-head SL4-FF Evo thanks to the 2 extra heads allows the 4 corners of the PVC frame to be welded simultaneously with 1 cross (front welding), cleaning (patented seamless welding) or retouching

The natural development of the 4-head SL4-FF Evo thanks to the 2 extra heads allows the 4 corners of the PVC frame to be welded simultaneously with 1 cross (front welding), cleaning (patented seamless welding) or retouching

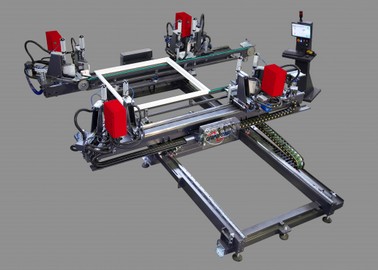

SL4-FF EVO

The world’s first and only 4-head CNC welder that completely eliminates the weld from the corner, allowing you to get PVC windows with consistent quality and excellent aesthetics.

A machine of its kind, it performs perfect welding, guaranteeing absolutely flat and homogeneous surfaces with profiles that contain products that cannot be welded instead of metal reinforcement, such as fiberglass, aluminum or other components.

A machine of its kind, it performs perfect welding, guaranteeing absolutely flat and homogeneous surfaces with profiles that contain products that cannot be welded instead of metal reinforcement, such as fiberglass, aluminum or other components.

SL2-FF EVO

The world’s first and only 4-head CNC welder that completely eliminates the weld from the corner, allowing you to get PVC windows with consistent quality and excellent aesthetics.

It ensures perfect and simultaneous welding of the angle 2, guaranteeing absolutely flat and homogeneous surfaces with profiles that contain non-weldable products such as fiberglass, aluminum or resin instead of reinforcing the metal.

It ensures perfect and simultaneous welding of the angle 2, guaranteeing absolutely flat and homogeneous surfaces with profiles that contain non-weldable products such as fiberglass, aluminum or resin instead of reinforcing the metal.

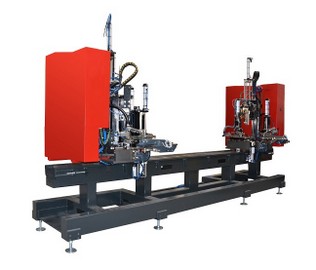

SL4-4

4-head CNC welding machine with 3 controlled shafts, designed for horizontal and simultaneous welding of four corners of PVC frame; provides the frame manufacturer with consistent operational quality over time.

It automatically performs all necessary operations, positioning at the welding sites, cyclic fusion, compression and cooling, and at the end of the process releases the conveyor frames to the cleaning area.

It automatically performs all necessary operations, positioning at the welding sites, cyclic fusion, compression and cooling, and at the end of the process releases the conveyor frames to the cleaning area.

SL4-U

4-head CNC welding machine with 3 controlled shafts, designed for horizontal and simultaneous welding of four corners of PVC frame; provides the frame manufacturer with consistent operational quality over time.

It automatically performs all necessary operations, positioning at welding sites, cyclic fusion, compression and cooling, and at the end of the process releases the conveyor frames to the cleaning area

It automatically performs all necessary operations, positioning at welding sites, cyclic fusion, compression and cooling, and at the end of the process releases the conveyor frames to the cleaning area

SL4-FS

Extremely fast CNC 4-head, 7-axis welding machine that provides the window manufacturer with consistent operational quality over time and up to a 50% increase in production.

Designed for horizontal and simultaneous welding of the 4 corners of a PVC frame, it automatically performs all the necessary operations of placing the welding position, cyclic fusion, compression and cooling, and, at the end of the process, it releases the frame conveyor belts towards the cleaning area.

Designed for horizontal and simultaneous welding of the 4 corners of a PVC frame, it automatically performs all the necessary operations of placing the welding position, cyclic fusion, compression and cooling, and, at the end of the process, it releases the frame conveyor belts towards the cleaning area.

SLV

Welding machine with very high precision welding system, variable angle between 30 ° and 180 °, for welding large profile profiles up to 200 x 200 mm at 90 °.

The device allows quick and easy adjustment from different angles and an optimal control of the temperatures of the welding plates and welding seam limiting knives thanks to a reliable and safe electronic device.

The device allows quick and easy adjustment from different angles and an optimal control of the temperatures of the welding plates and welding seam limiting knives thanks to a reliable and safe electronic device.

SL5 UNI

High-precision welding machine that allows simultaneous welding of 90 ° angles and “T”, “Cross” or “H” crossmembers (in any combination) and variable angle welding between 35 ° and 180 ° in a single operating cycle . °.

The unit also allows the two ends of the crossmember to be welded simultaneously by rotating the two of the five heads 90 °.

The unit also allows the two ends of the crossmember to be welded simultaneously by rotating the two of the five heads 90 °.

SL4 UNI

High-precision machine that allows simultaneous welding of 90 ° angles and “T”, Cross or “H” crosses (in any combination) and variable angle welding between 35 ° and 180 ° in a single operating cycle.

The unit also allows the two ends of the cross member to be welded simultaneously by rotating the four heads 90 °

The unit also allows the two ends of the cross member to be welded simultaneously by rotating the four heads 90 °

SL3 UNI

High-precision machine that allows simultaneous welding of 90 ° angles and “T”, Cross or “H” crosses (in any combination) and variable angle welding between 35 ° and 180 ° in a single operating cycle.

The unit also allows the two ends of the tank to be welded simultaneously at 90 ° to the three heads.

The unit also allows the two ends of the tank to be welded simultaneously at 90 ° to the three heads.

SL2 UNI

High-precision machine that allows simultaneous welding of 90 ° angles and “T”, cross or “H” crosses (in any combination) and variable angle welding between 35 ° and 180 ° in a single operating cycle.

The unit also allows the simultaneous welding of both ends of the cruise ship by rotating both heads 90 °.

The unit also allows the simultaneous welding of both ends of the cruise ship by rotating both heads 90 °.

SLTV

High precision welding machine capable of welding "T", "Cross" or "H" (notch welding) at ends and at variable angles between 35 ° and 180 °.

Cross-welding is performed on pointed and cut profiles with a relative "V" notch.

The device allows quick and easy adjustment from different angles and an optimal control of the temperatures of the welding plates and welding seam limiting knives thanks to a reliable and safe electronic device.

Cross-welding is performed on pointed and cut profiles with a relative "V" notch.

The device allows quick and easy adjustment from different angles and an optimal control of the temperatures of the welding plates and welding seam limiting knives thanks to a reliable and safe electronic device.

SL2-2

Double head welding machine with fixed angle, ideal for 90 ° welding of 2 angles in a single work cycle.

It is equipped with a very stable device, a reliable and safe electronic device that guarantees optimal and homogeneous control of temperature, welding plates and welding bead limiting knives.

It is equipped with a very stable device, a reliable and safe electronic device that guarantees optimal and homogeneous control of temperature, welding plates and welding bead limiting knives.

SL2V E

High precision machine that allows the welding of a single angle to be variable measure between 35 ° and 180 °, or alternatively the welding 2 angles of 90 ° for a single duty cycle.

The device allows quick and easy adjustment from different angles and an optimal control of the temperatures of the welding plates and welding seam limiting knives thanks to a reliable and safe electronic device.

The device allows quick and easy adjustment from different angles and an optimal control of the temperatures of the welding plates and welding seam limiting knives thanks to a reliable and safe electronic device.